So Concrete Builds a Sustainable Transit Stop in Prague

Employing robotic fabrication and a super-strong mix of the material it’s titled after, So Concrete has built a sturdy and sustainable transit stop in Prague.

After being awarded a commission by the city of Prague to design the Výstaviště tram stop from 3-D printed ultra-high-performance concrete, local multidisciplinary studio So Concrete enhanced an initial AI rendering with a 1:50 scale model of the structure’s canopy.

How So Concrete Built a Sustainable Tram Stop

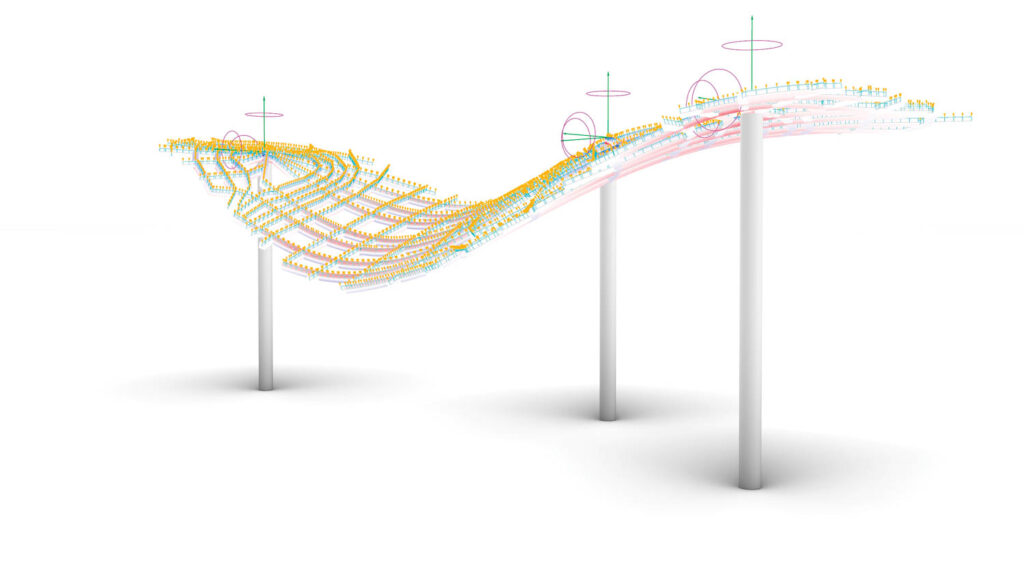

In conjunction with engineering consultant Stráský, Hustý, a more detailed rendering was made with Rhinoceros.

Another rendering examines the three columns supporting the canopy and bench to determine the least amount of steel needed, thereby reducing the project’s energy use.

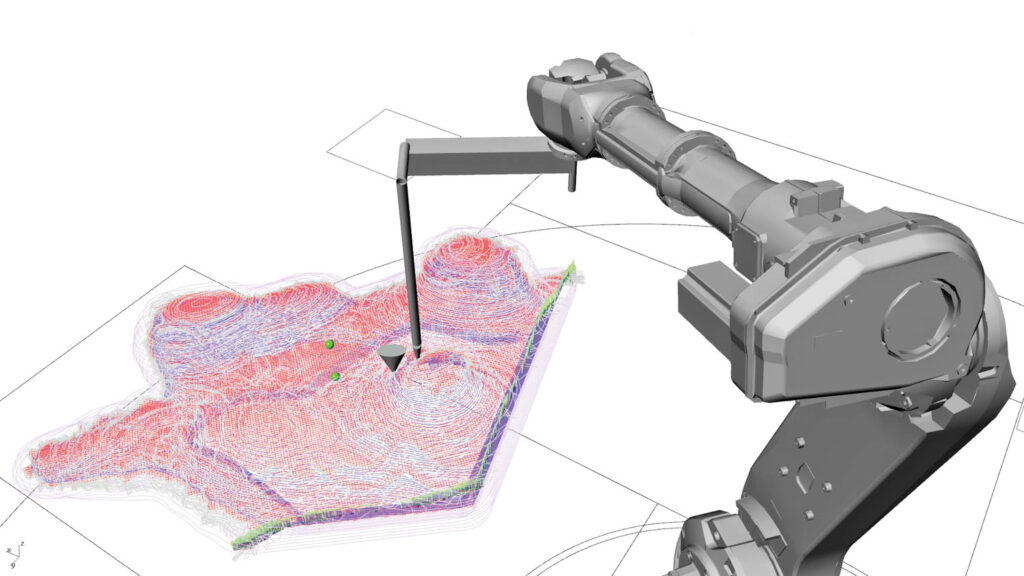

Trajectories of a six-axis robotic arm were mapped out before the 3-D printing process, which resulted in a compression strength five times that of regular concrete.

A material specialist at So Concrete prepared the UHPC, modified to ensure optimal printing for the canopy and bench, which were both printed in six pieces before being assembled on-site.

The Stats

- 10 engineers, designers, concrete technologists, and robot operators led by robotic engineer Dimitry Nikitin and designer Záviš Unzeitig

- 36 hours to 3-D print the basic structure

- 26 foot canopy length

- 15 days of installation

- 60% of comparable material saved

The base of the tram stop, which is located in the art-centric Prague 7 district, is UHPC that has been robotically milled with graceful arches.

Panels of laser-etched Plexiglas form the backrest for the bench and cap the 9-foot-high canopy, both of which are made of tinted, 3-D printed UHPC that’s been robotically cut.

Furthering the project’s sustainability, electronic displays showing timetables for the city’s 38 tram routes are solar-powered, all helping to encourage the use of public transportation instead of cars.

read more

Projects

Through Adaptive Reuse, Studio Alexander Fehre Turns Two Buildings into a New Facility in Germany

Studio Alexander Fehre turns two buildings into a playful special-projects facility at the Bosch Engineering headquarters in Germany.

Projects

Rockwell Group Earns a Best of Year Award for the Moynihan Train Hall in New York

2021 Best of Year winner for Transportation – Small. Rockwell Group designed a ticketed waiting area for Amtrak and Long Island Railroad customers that brings the glamour back to travel.

Projects

The Bor̆islavka Center by Aulík Fišer Architekti Reflects Prague’s History

The dramatically faceted glass facades of the Borislavka Center by Aulík Fišer Architekti reflect Prague, old and new.

recent stories

DesignWire

A Contemporary Art Center Blooms Inside An 1893 Eiffel-Style Icon

Jakob+MacFarlane reimagines a historic textile warehouse as Frac-Artothèque Nouvelle-Aquitaine, a 21,000-square-foot contemporary art center.

DesignWire

10 Questions With… Chris Gustin

Ceramic artist Chris Gustin dives into the dynamic exploration of movement and nature in his largescale works and his show at the Donzella gallery.

DesignWire

A Career In Color: Explore Olga De Amaral’s Retrospective In Miami

Explore a different perspective on color with textile artist’s Olga De Amaral’s retrospective at the Institute of Contemporary Art, Miami.